2019 Performance

Total water withdrawal in calendar year (CY) 2019 was over 50 million cubic meters (m3) for our manufacturing sites. This figure is up from our CY18 use and reflects increased capacity. While this water consumption figure is large, our global water recycling initiatives at manufacturing sites achieved an approximate 50% recycling rate on average in that same period.

We are working toward our aspirational goal of reusing, recycling or restoring 100% of the water used in our operations. Actions such as enhancing reuse and recycling infrastructure and water efficiency management will help us make progress toward this goal. A key opportunity for us to increase water recycling is through capacity expansion projects. Increasingly, we are incorporating water-saving measures at the design stage of new buildings and industrial processes at the same time as we invest resources to improve water use efficiency at existing factories.

Managing Our Water Use

Sustainable management of our water footprint begins with understanding where we obtain water. Globally, the primary source for water at manufacturing locations is municipal supply, underscoring the importance of partnerships with local water authorities. We consider these relationships within their local context, seeking to understand the implications of different geographies, climates, watersheds and infrastructure. We then apply these assessments to determine the best approach to water management at each site.

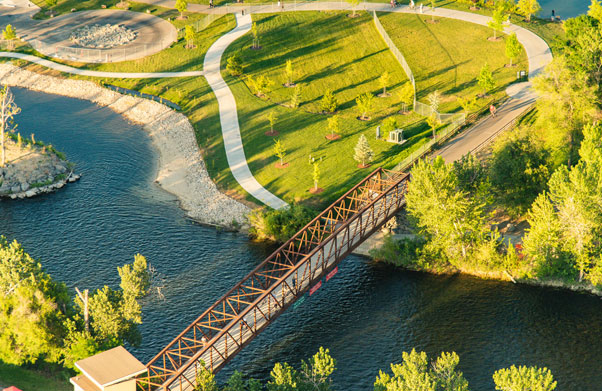

A water risk assessment using the World Resources Institute (WRI) Aqueduct tool has helped us better understand local water conditions. Through this assessment, we learned that 47% of Micron’s total water withdrawals are sourced from water-stressed areas, primarily our manufacturing locations in Singapore, China and Taiwan. The U.S. and Japan are additional water-stressed areas where we have significant manufacturing capacity. We take a blended approach to water management in these parts of the world. In addition to water reclamation systems at our wafer fab facilities, we have installed rainwater capture infrastructure at our expanded North Coast fabrication site in Singapore, and we source 98% of our water from reclaimed and/or desalination facilities. At our wafer fab in Taoyuan, Taiwan, we installed a new wastewater reclamation system in 2019 that reduces our annual municipal water consumption by over 450,000 m3. And in Boise, Idaho, we understand our potential impact on the aquifer that supplies the majority of water locally. We were early investors in technology that allows us to replenish the aquifer and mitigate the effects of withdrawal.

While our approach to water supply and consumption mitigation reflects a local, adaptive approach, our commitment to ensuring that industrial wastewater discharges meet all environmental legal requirements is universal. Each Micron site has invested in significant water treatment infrastructure to ensure that the quality of any wastewater leaving the site meets or exceeds applicable water quality standards. The sites also have staff responsible for the ongoing operation and routine maintenance of wastewater systems to ensure proper performance over time. Wastewater treatment methods may vary by site but include membrane filtration, ion-resin adsorption, precipitation, bio-oxidation and neutralization. We routinely sample wastewater discharges for conformance to environmental standards. In CY19, we discharged 39 million m3 of treated wastewater, with 85% of that discharge sent to publicly operated treatment works.