Environment

Meeting demand for refrigerated products responsibly

Refrigerants account for 12 percent of our global GHG footprint, contributing nearly twice that of the fuel used in our trucks. As demand for our retail services expands globally, especially for fresh and frozen food, the need for refrigerated equipment will continue to grow. We’re committed to becoming more sustainable in this area, while working to ensure safe, reliable and affordable food to our customers around the world.

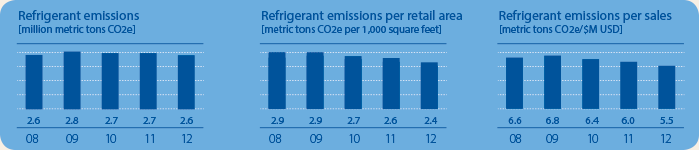

Our work in this area has driven a greater than 8 percent decrease in total annual GHG emissions from refrigerants in our 2005 base of stores and clubs. Furthermore, we continue to see the growth rate of our refrigerant emissions decrease at all our facilities, when compared to both sales and square footage. This suggests we’re using them more effectively than ever before.

We continue to produce results by applying industry best practices and by remaining committed to a refrigerant strategy that focuses on:

- Prevention: We aim to prevent refrigerant leaks by properly maintaining systems and avoiding accidental ruptures, as well as by streamlining our global equipment specifications. These measures utilize factory-built, quality-controlled systems that have fewer leaks than custom systems constructed on site.

- Reduction: Through the use of more efficient equipment and facility design, we can reduce the demand for refrigerant-using equipment to cool our facilities.

- Transition: We continue to explore refrigerants with reduced Global Warming Potential (GWP) and Total Equivalent Warming Impact (TEWI), including HFC replacements, natural refrigerants and hybrid systems. Our intention is to phase down our overall reliance on high-GWP refrigerants and reduce energy consumption.

Phasing down HFCs

We continue to evaluate feasible alternatives to conventional refrigerants, from both a GWP and TEWI perspective. In November 2010, former President and CEO Mike Duke and others from the Consumer Goods Forum signed a resolution “to begin phasing out HFC refrigerants by 2015 and replace them with non-HFC refrigerants where these are legally allowed and available for new purchases of point-of-sale units and large refrigeration installations.”

In 2011, we began incorporating refrigeration and store designs that would enable the transition to less HFC-reliant systems. We’ve also begun testing full HFC-free systems in several markets. These experiments will allow us to validate system efficiency, total GHG impact and quality functionality.

U.S.

- 168 Stores and 2 Sam’s Clubs fitted with glycol and CO2

- Washington, D.C. H Street store deployed Walmart U.S.’s first natural low temperature system

- World-class refrigeration lab carrying out independent trials

- Integral systems with water loop

- 6 glycol secondary systems

- Cascade CO2 with ammonia primary system in our new Distribution Centers

- Cascade CO2 with ammonia is primary system

- 9 stores transcritical CO2

- Glycol refrigeration systems on MT

- Burlington store CO2 secondary system

- Quebec store high side hydronic heat recovery

- Guelph store 100% natural low temperature

- Balzac Distribution Center uses ammonia as coolant. Building is 60 percent more energy efficient than other DCs